(630) 682-4700

2655 Warrenville Road, Suite 225, Downers Grove, IL 60515

Better information about your collection, water, and stormwater systems

Explore ClarityBetter information about your collection, water, and stormwater systems

Explore Clarity

Mr. Gallin possesses a robust knowledge of collection and distribution system ...

Force mains are a bit of an enigma in the municipal infrastructure landscape. They are critical system assets with a very high consequence of failure, comprising approximately 7.5 percent of all wastewater pipes (EPA, 2010). However, typically, only a few basic details are known about them. Many communities constructed their collection systems between the 50s and 80s with a designed service life of up to 70 years. So approximate pipeline ages can be established, but actual force main conditions are a mystery beyond that. With so many systems reaching the end of their anticipated service life, it is only a matter of time before failures occur.

To complicate matters, inspecting force mains can seem like an insurmountable challenge. Many pipelines traverse thousands of feet between access points, and traditional inspection methods call for complete pipeline shutdowns, which require costly bypass setups. So, the question is,

How can system owners cost-effectively evaluate the condition of their force mains?”

The answer is screening level assessments (SLA), a phased, cost-effective way to identify defects and separate the good pipeline from the bad.

The first step to performing an SLA is conducting a desktop assessment by reviewing all known information about the force main—as-built records, maintenance and break history, and pumping data—to understand any operational anomalies. The system is then further reviewed to identify access options, prioritize inspection locations, and understand potential flows that will affect inspection planning.

Site visits and field reconnaissance are conducted to assess the lift station’s performance, confirm insertion points, and inspect the discharge manhole (and subsequent manholes if the effect of hydrogen sulfide corrosion is visible). For most lift stations, existing check valves within the valve vault can be utilized for insertion. The downstream discharge manhole’s inlet pipe determines the retrieval setup.

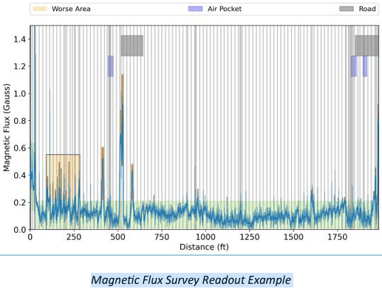

Selecting the appropriate screening device to perform an internal assessment while keeping the force main in service is a major factor in controlling costs. RJN has had success using Ingu Solutions’ Pipers®, an in-pipe, free-floating, multi-sensor technology that is easily mobilized by our engineers. These devices can effectively assess up to 108-inch diameter pipelines of virtually any length. Pipers simultaneously collect acoustic data to identify leaks and air pockets; record pressure fluctuations due to flow restrictions or debris build-up; and conduct magnetic flux surveys to determine gross wall loss in metallic pipelines.

Selecting the appropriate screening device to perform an internal assessment while keeping the force main in service is a major factor in controlling costs. RJN has had success using Ingu Solutions’ Pipers®, an in-pipe, free-floating, multi-sensor technology that is easily mobilized by our engineers. These devices can effectively assess up to 108-inch diameter pipelines of virtually any length. Pipers simultaneously collect acoustic data to identify leaks and air pockets; record pressure fluctuations due to flow restrictions or debris build-up; and conduct magnetic flux surveys to determine gross wall loss in metallic pipelines.

Pipers pressure monitoring surveys have been an extremely effective RJN tool for identifying pipeline debris and build-up. These deposits limit the hydraulic capacity of pipes and risk the integrity of the pipeline due to abrasion.

During a recent 6-inch force main study, the magnetic flux survey identified two potentially corroded sections of the pipeline that were prioritized for replacement due to their location at a roadway crossing and a nearby inoperable air release valve. In another 24-inch force main study, the Pipers identified a section of pipe with an air pocket and potential deterioration due to hydrogen sulfide corrosion. A broadband electromagnetic assessment was recommended to confirm any wall loss before replacement due to the larger size of the pipe.

During a recent 6-inch force main study, the magnetic flux survey identified two potentially corroded sections of the pipeline that were prioritized for replacement due to their location at a roadway crossing and a nearby inoperable air release valve. In another 24-inch force main study, the Pipers identified a section of pipe with an air pocket and potential deterioration due to hydrogen sulfide corrosion. A broadband electromagnetic assessment was recommended to confirm any wall loss before replacement due to the larger size of the pipe.

However, before utilizing Pipers, there are a few considerations to be taken into account. Pipelines must be at least two inches in diameter, remain full for the duration of the assessment, and flow velocities ideally should be within two to six feet per second. In most cases, these requirements can be easily met with a little bit of planning.

Executing the assessment is relatively straightforward. After performing flow calculations to determine the Pipers’ travel times, at least two Pipers will be inserted into the line. Consecutive runs through a pipeline deliver additional layers of information that enhance inspection quality and reliability. In addition, this vital information on a pipeline’s performance can be delivered at a fraction of the cost by minimizing mobilization costs.

Assessing a force main is a highly specialized service, but that does not mean it has to be a massive effort or an exorbitant budget hit. Using the appropriate pre-planning assessment strategies and coupling those efforts with the most advantageous technologies will deliver actionable intelligence. The results of a successful SLA provide system owners with three primary courses of action: targeted recommendations for follow-up studies; rehabilitation recommendations; or conditions warrant no further action.

Mr. Gallin possesses a robust knowledge of collection and distribution system ...